Waste Transformer Oil Distillation Plant

Basic Info

Model No.: ZL-8

Product Description

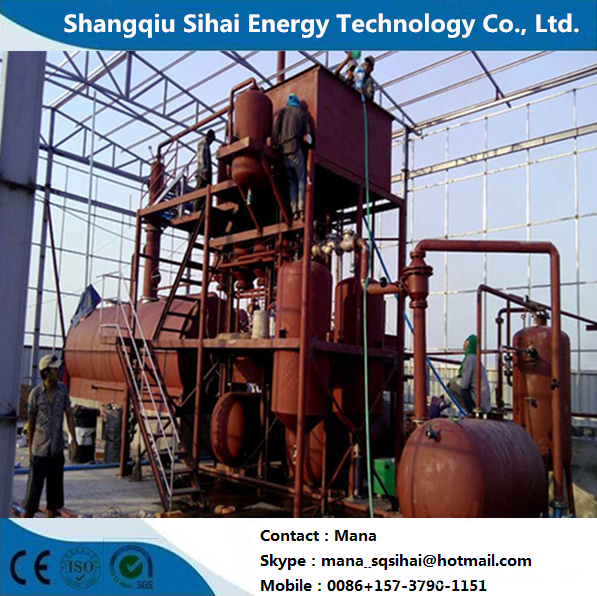

Waste Transformer Oil Distillation Plant

Technical parameter of the Waste Transformer Oil Distillation Plant

| Model | Structure form | 24 hours handing capacity |

| ZL-8 | Vertical\ Horizontal | 10-15tons crude oil\plastic oil\tire oil |

| Reactor size | Work pressure | 24 hours oil production |

| (Dia)2000*(L)4000 | Negative pressure\ Vacuum | 9-13.5 tons (10-15%gasoline 70-75%diesel) |

| Area need | Cooling system | Heating method |

| 300 square meters | Water cooling | Directly\Auxiliary\Electric heating |

| Power | Installation | Delivery time |

| 16KW | Have basis | 20 days |

Characters of the Waste Transformer Oil Distillation Plant

Vacuum Pressure Distillation,is the new technology which can refine the tire oil , plastic oil , waste engine oil, sludge, motor oil and so on into base oil(which can be made into diesel and gasoline after processed by our catalyst). The oil quality is better than the original normal pressure distillation technology, which show on purity ,transparence, lightness .this technology will do deodorization and destinke process to the raw material oil automatically by "dry type" vacuum pressure distillation method. With the vacuum distillation technology, the distillation temperature is considerably reduced, and the oil output will higher 5%-10% compared with original normal pressure distillation technology. It makes more profits to the enterprise virtually.

Vacuum Pressure Distillation plant is operated under vacuum pressure in 24-hours continuous working form .During the refining process of oil ,there will be some waste gas produced which can not be condensed in the process .Those gas will be fully burned in the special gas nozzle and produce a plenty energy ,which can economize resources efficient .For example, if you use coal to burn the reactor ,it will need 1.5tons coal to run 24hours without the waste gas combustion-supporting, but if with waste gas combustion-supporting , 0.5tons coal is enough to run with 24hours.

The desulphurization and dedust removal device on the system will ensure you air pollution free.

Processing system of the Waste Transformer Oil Distillation Plant

| Processing System | Function |

| Pretreatment System | Remove Water, colloid, and impurity and other content of Raw Material |

| Heating System | Supply heat for whole set machine running |

| Distillation (tower) System | Atmospheric Fractionator Ensure differrent Fraction come Out. |

| Refining filter System | Ensure Oil Quality Meeting Standards. |

| Vacuum System | Lower each fraction temperature, Reduce energy consumption,Improve the oil output and quality. |

| Oil-Water Separating System | Convert Oil Gas to be Oil Liquid and Ensure the Quality and Yield of Oil Liquid |

|

| High-effective converting Oil Gas to be Oil Liquid |

| NoncondensIble Gas Recycle System | Save energy, Ensure safty operation, Eco-friendly Emissions. |

| Dedust System | White Smoke, Eco-friendly Emission |

| Electric Control system | Semi-automatic working, not only greatly decrease potential risk and waste caused by human, Improve product quality and qty. |

| Self-made Catalyst Formula | Improve Oil Quality and Yield |

| Explosion-Proof System | Ensure Running Process Safety |

| Electrostatic Grounding System | Ensure Running Process Safety |

| Fire Safety System | Ensure Running Process Safety |

Main components of the Waste Transformer Oil Distillation Plant

a.Vertical reactor/Horizontal reactor

b.Reducer system

c.Condensation system

d.Collector

e.Oil collecting tank

f.Residue tank

g.Oil-gas separator

h.Water cooling system

i.Water seal

j.Pressure.Temperature monitoring gauge

k.Deodorization system

l.Efficient anti clog cooling system

m.Gas heating system (waste gas process system)

n.Smoke desulphurization and dust removal system

o.Total area150㎡

End production of the Waste Transformer Oil Distillation Plant

End Production Name Yield Usage Diesel 73% * Used for Engine Fuel Gasoline 12% * Used for Engine Fuel Residue Oil 9% * Feeding into Pyrolysis Machine for Pyrolysis * Used as heating fuel for Distillation machine Non-Condensible Gas 3% * Recycle as Heating fuel after treated by Gas-treatment System Other 3% * Water and impurity 2% * Loss 1%

Benefits analysis of the Waste Transformer Oil Distillation Plant

Production raw material cost :(AS our model ZL-7 as sample in market this year)

The price of crude oil from waste tire or plastic is USD700/ton

Other consumption cost :

a. Coal:running 24 hours need 800KG*USD165/ton=USD135

b. Water and electricity: USD40 per 24hours

c. Two workers` salary per day:USD100 *2=USD200

d. Eequipment depreciation:=USD20

e. Taxes: free of charge

g. total:USD395

Value of product:

the cost of national petroleum is USD 1200/ton

B. The cost of final oil from our equipment is USD 1100/ton

C. the convertion of crude oil (from waste tyre ,plastic)is 80%-90%

The value of product per day is 10tons *85%*USD 1100=USD9350

Product Categories : Waste Oil Distillation Plant > Waste Transformer Oil Distillation Plant